Top Lessons You Can Use from Businesses Effectively Overcoming Rising Supply Costs

Supply chain cost increases remain a challenge for small business owners. 56% of retailers experience moderate disruption as a result of the pandemic. On top of that, natural disasters from hurricanes to massive fires in the West are putting supply chain management to the test.

28% of companies are experiencing shortages and are trying to find alternative sourcing options. The good news is that you are not alone. Your competitors are dealing with the same issues, and emerging supply chain management technologies offer hope.

What You Can Learn from Others

The massive supply chain management crisis has brought out the best in people, allowing intense creativity and ingenious improvements. To help provide inspiration, here are some of the best ideas that you can use to get your business through this supply chain disruption.

Many Businesses Use Advanced Technologies

New technologies are already having an impact on supply chain management, increasingly embraced by many businesses. From AI to real-time tracking and analysis, these technological advancements are offering hope for the future. AI and machine learning can find the most cost-effective delivery methods. Robotics and automation are used to improve material handling and energy savings. As an example, robots working without lights achieve 20% in energy savings.

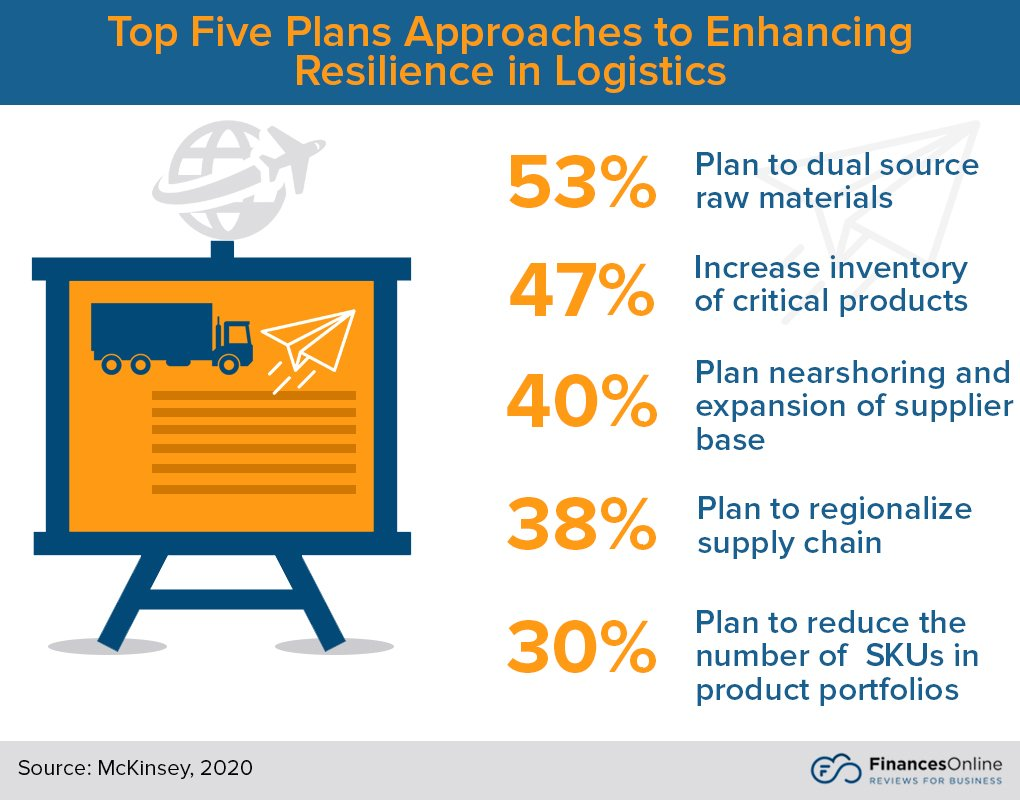

Businesses Stock More Inventory

The delays and shortages caused by the pandemic have caused many business owners to keep more stock on hand as a safety net, especially for items that frequently sell out. Companies also benefit by streamlining inventory administration with inventory management tools like TradeGecko, Primaseller, or Zenventory.

Dual Sourcing of Raw Materials or Goods

Cross-sourcing, dual-sourcing, or multi-sourcing are new considerations for many small companies in the new age of supply chain management. Using two or more suppliers can put you in a better position when there are shortages or delays. There are some drawbacks to multi or dual sourcing. Quality and service will vary, so be prepared to make adjustments if you have been used to a certain standard. Ultimately, it comes down to weighing the challenges and the benefits and making the best decision for your unique situation.

ESG Creates a More Robust Supply Chain

Small and large companies increasingly face pressure from consumers and regulatory agencies to be more socially and environmentally responsible. Still, it is a little-known fact that ESG adherence benefits supply chain management. Many organizations reduce energy consumption and add electric and solar-powered vehicles to lower their carbon footprint and reduce costs. A study by the Capgemini Research Institute has found that over 77% of organizations recognize the need for change and are making their supply chains more sustainable.

Sometimes, the Only Option is to Raise Prices

Some businesses offer value-added solutions to offset the consequences of increasing prices. For example, a software company may provide a 20-minute free consultation session with the purchase of their product. Alternatively, they may provide free or discounted support services. Providing stellar customer service can provide a competitive advantage. It is not as challenging as many business owners fear because everyone is in the same situation. Competitors are raising their prices too. Consumers are aware of these challenges, understanding that they can’t just go elsewhere to find cheaper prices.

The Shut Down has Provided Enduring Lessons

Some companies have benefited from some shut-down-related adjustments. For example, businesses can expand their customer base and increase profits by adding e-commerce capabilities to their brick-and-mortar stores. Other shopping methods, such as curbside pickup and delivery, also provide additional options for customers.

Sourcing Locally Can be Cost Effective Again

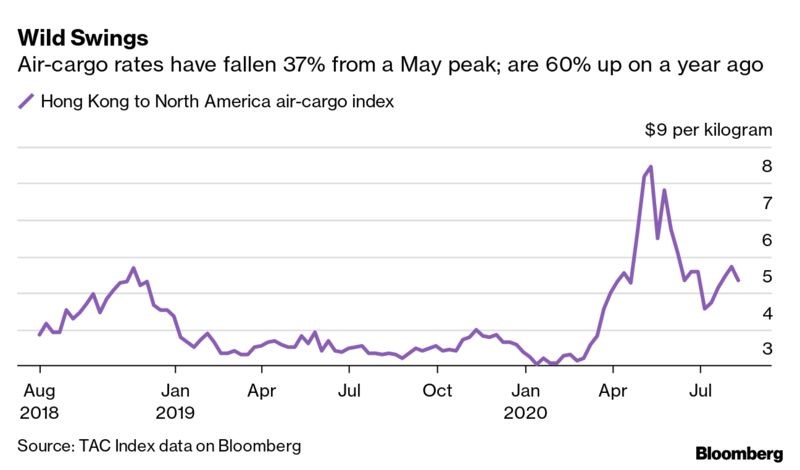

Companies went abroad for goods and raw materials due to the cheaper labor costs, which helped offset extra transportation costs. But the math has changed. Nearsourcing or nearshoring is something that many businesses are switching to, now that the escalating transportation cost has changed the game.

The trends, insights, and solutions you need to grow your business.

By signing up, you’re subscribing to our monthly email newsletter, The

Wire. You may unsubscribe at any time.

Your information stays safe with us. Learn more about our privacy

policy.

![[#MSP_NAME#] Logo](/themes/sparklight_business/images/transition-logos/migration-banner-logo-[#MSP_CD#].png)